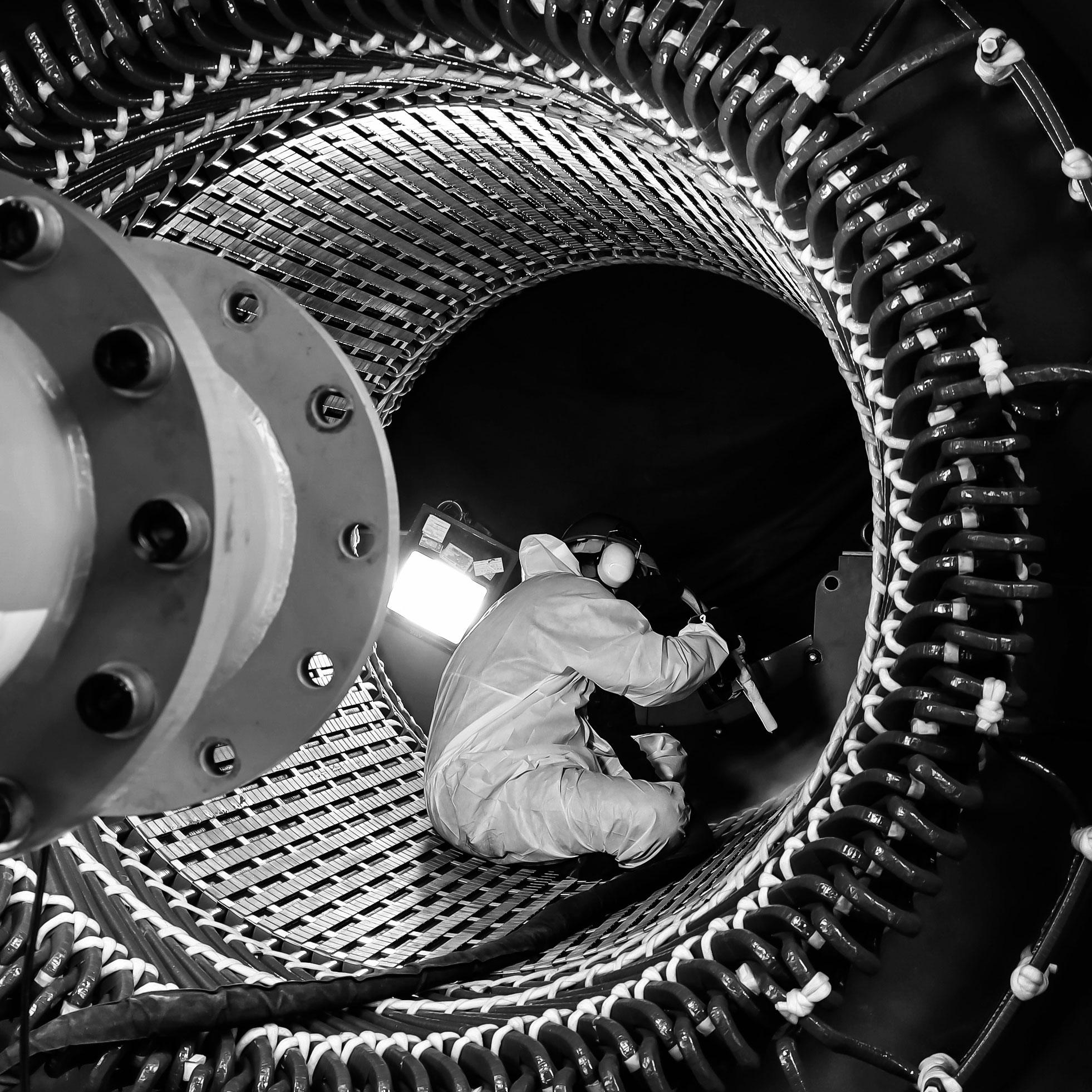

Saltend Chemical Park – TAR Piping & Auxiliary Systems + Pumps & Motors

Provided our OEM customer with a Project Team Solution for the TAR (Turnaround) of the BP chemical plant in Hull, United Kingdom. Crew was comprised of:- Platers/Fabricators x16

- Welder (Coded) x12

- Mechanical Fitter x24

- Riggers x8

- Crane Operators x2