Installation

Site assessment, preparation, and leveling

Transportation of wind turbine components to the site

Replace worn or damaged components, such as bearings and seals

Foundation installation, including excavation, reinforcement, and concrete pouring

Tower assembly and erection, including sections, ladders, and cabling

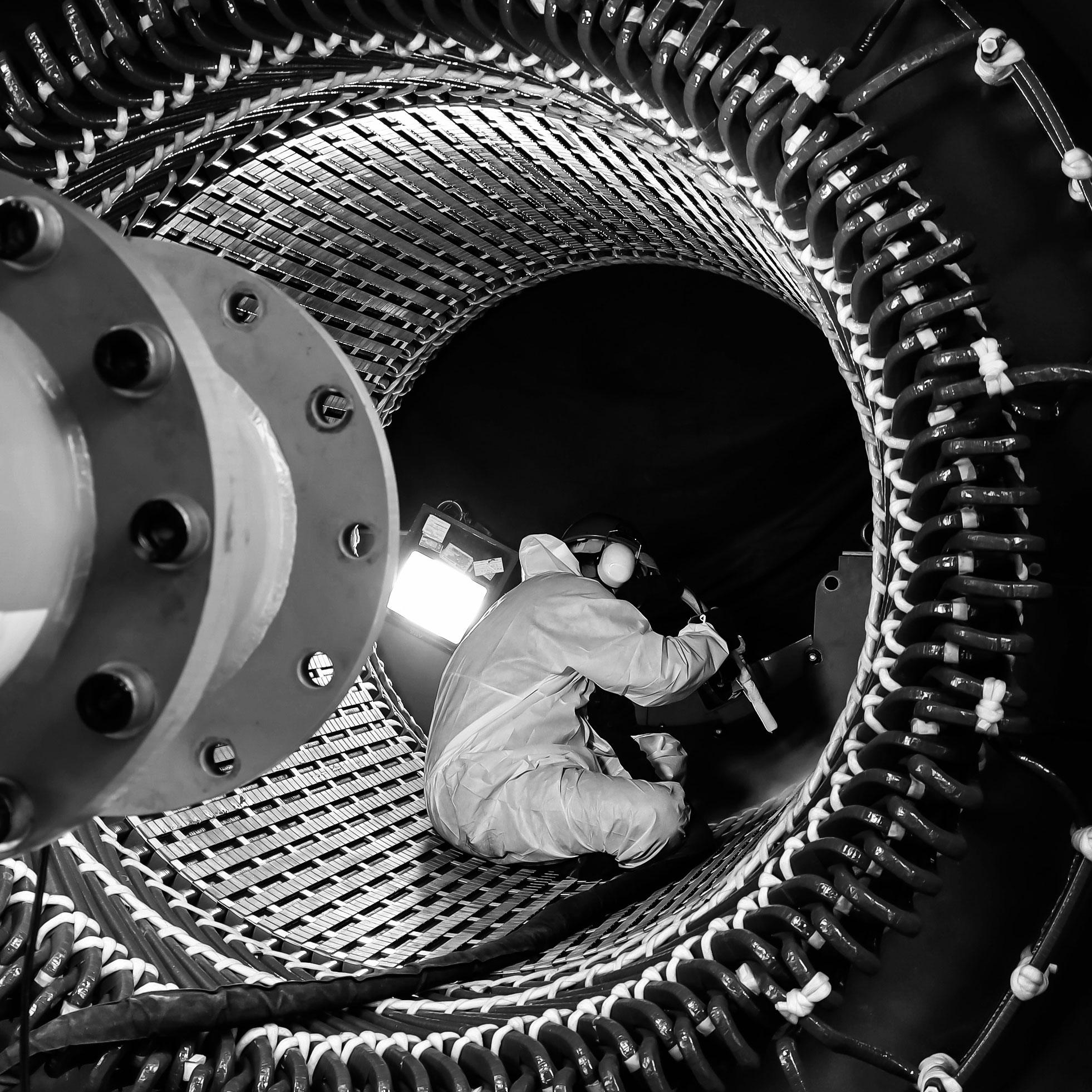

Nacelle installation, including gearbox, generator, and control systems

Rotor and blade assembly, including pre-assembly on the ground and hoisting into position

Electrical and mechanical connections, including power cables, transformers, and grounding systems

Meteorological equipment installation and calibration

Global

Partnerships

-

Saltend Chemical Park – TAR Piping & Auxiliary Systems + Pumps & Motors

Provided our OEM customer with a Project Team Solution for the TAR (Turnaround) of the BP chemical plant in Hull, United Kingdom. Crew was comprised of:- Platers/Fabricators x16

- Welder (Coded) x12

- Mechanical Fitter x24

- Riggers x8

- Crane Operators x2

-

Humber Refinery Phillips 66 – TAR Piping & Auxiliary Systems + Pumps & Motors

Provided our OEM customer with a Project Team Solution for the TAR (Turnaround) of the Phillips 66 refinery in Humber, United Kingdom. Crew was comprised of:- Platers/Fabricators x16

- Welder (Coded) x12

- Mechanical Fitter x24

- Riggers x8

- Crane Operators x2

Commissioning

Initial system tests, including mechanical, electrical, and control system checks

Verification of the proper functioning of safety systems, such as brakes, emergency stops, and lightning protection

Inspection and testing of the wind turbine’s structural and mechanical integrity

Blade pitch angle calibration and rotor balancing

Functional tests, including yaw system checks and generator synchronization

Performance tests, including power curve validation and efficiency assessments

Grid integration tests and verification of grid compliance

Training of on-site personnel for operation and maintenance

Final documentation, handover to the client, and project closeout